Our exploration of the various solutions of this blog has brought us through regulatory fishing and shipping policies, independent clean-up initatives, recycling the product life cycle and end of life disposal treatment, zero waste, green marketing and plastic-free lifestyle movements. In this final post of the series on the solutions to plastic pollution, we examine the frontier of technology and scientific innovation.

Plastic, as we have known and come to know through our journey in this blog, is a unique material–durable, lightweight, and almost lasts forever. The very same characteristics that accord plastic its strength and usefulness as a material, are the very same characteristics that make it one of the most problematic substances on the planet. It is sourced from crude oil, a finite fossil fuel, and is non-biodegradable, contributing to both unsustainability, global warming and also causing plastic pollution.

Now then, what if we say that these problematic characteristics of plastic and processes of biodegradation can be changed? What if the very nature of plastic and biodegradation can be transformed? Innovations in science has presented these possibilities of making bio-degradable plastics and biologically-sourced types of plastics known as “bio-plastics”. Indeed, one go back to nature and forward in technology at the same time. In this post, we will explore first the innovation of bioplastics then technologies of biodegradation.

Bio-Plastics

To begin, what is a bio-plastic? Bio-plastics, or biologically based polymers, are plastics created from renewable bio-energy sources. The term is generally used to differentiate them from plastics derived from the conventional source of petroleum. It is important to note, however, that not all bio-plastics are biodegradable. The biodegradable variety of bio-plastics are made using renewable resources such as plant biomass, and will biodegrade under certain environmental conditions. They are comparatively more sustainable as they save fossil fuel resources, and support further plant growth if disposed of properly. The non-biodegradable variety of bio-plastics, on the other hand, are also using renewable resources but are designed to have a longer life span for durability. They are useful in weight-dependent applications such as in metal components of cars, increasing fuel efficiency from lighter weight.

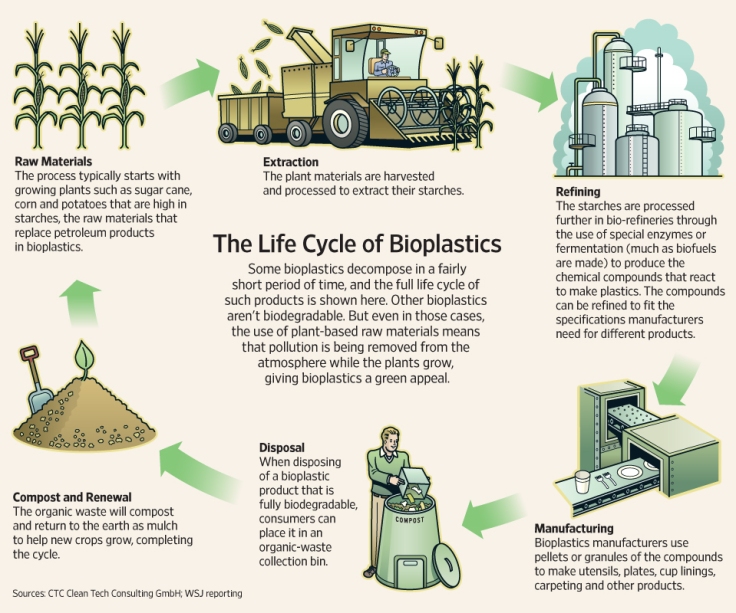

As summarised in the above diagram, plastics created from biological sources have a circular life cycle, originating from biological material and returning to become one upon decomposition. Recent exciting developments include new materials produced from starch, cellulose, and those derived from processes of microbial fermentation.Starch is a renewable and commonly available raw material, and has been the primary focus of innovative efforts. Starch is economically competitive with petroleum and has been used in several methods for preparing compostable plastics. Corn is the primary source of starch for bioplastics, and the following video demonstrates how bioplastics can be made from it. Research is ongoing on the potential of using rice, barley, wheat, oat, soy and potato sources of starches for bioplastics.

Unfortunately, current production and commercial levels in bioplastics is still unable to meet the demands of replacing the 8% of world oil production directed to plastics manufacturing. Deriving bioplastics from food sources may still not make it cost competitive as they compete in raising food prices. Research could be done to extract sugars from low quality biomass including yeast, bacteria and algae. The ideal future of manufacturing commercial bio-based polymers on a global scale has not been realised as of today, but is something that current research work towards. However, with governments around the world taking the stand of reducing plastic use, support and effort invested in plastic innovation technologies are likely to grow more intensely in the coming years. As discussed in earlier posts, France recently banned non-biodegradable plastic cutlery, plates, and cups and many countries such as Singapore have adopted zero waste goals. Globally, the Paris climate talks companies have committed countries to finding new industrial supply chains independent of fossil fuels. Given the supportive environment, it is very possible for the right materials are found to the bioplastics of the future.

Nevertheless, in current stages of technology where conventional plastics derived from petrochemicals are used, research can be done in changing the processes of biodegradation. Plastics can have additives to speed up their degradation, or the usage of living organisms and setting up of environmental conditions for it.

Bio-Degradable Plastics

This section, then, explores the technologies of biodegradation in plastic. Biodegradable plastics which are still petrochemical-based are derived from conventional crude oil and fossil fuels but designed such that they can be biodegraded by the microbes in the soil, compost or oceans. Under the proper conditions, biodegradable plastics can be decomposed by the action of living organisms, until they are completely metabolised to carbon dioxide and water.

For this to be beneficial,it is crucial for there to be proper sorting of plastics into correct categories. Mixing some degradable plastics with other recycled plastics would still reduce the performance and life span of the end products. Moreover, not all biodegradable products are suitable for composting. There are compostable and non-compostable biodegradable plastics and these depend on the conditions such as time, temperature and the environmental effects. Compostable plastics allow for composting of a much larger position of nonrecoverable solid waste, as they can mix with other organic wastes, enabling commercially viable and economically sustainable composting.

However, the reality is that current technology remains limited and even biodegradable plastics still produce pollution and greenhouse gas production concerns. The video below summarises and explains some of the issues of biodegradable plastics. Biodegradable and compostable plastics take a long time to degrade in the anaerobic environment of a landfill. Anaerobic digestion of organic materials also produces methane gas that, if not captured, adds to greenhouse gases in the atmosphere.

Nevertheless, there remains an alternative method to biodegradation, in the research of living organisms that can consume and degrade plastics by themselves. Some bacteria have developed the ability to digest plastics such as in two types of nylon eating bacteria, Flavobacteria and Pseudomonas, were found to produce enzymes capable of breaking down nylon. Research has also found there to be worms that are able to eat plastic. The following video sheds more insight on such possibilities of such organisms.

As such, technology presents virtually endless possibilities in overcoming the plastic pollution problem. While current research is only just beginning, with adequate funding and support, scientific innovation in biodegradation proccesses and bioplastics could finally produce plastics that can be buried and decomposed back to the soil and not something that “lasts forever”, in the words of the quote introduced at the introduction of this blog.

References

American Chemistry Council, (2016). What are Bioplastics? | Plastics Make It Possible. [online] Plastics Make It Possible. Available at: https://www.plasticsmakeitpossible.com/about-plastics/types-of-plastics/what-are-bioplastics/ [Accessed 1 Oct. 2016].

An Overview of Bioplastics. (2016). International Journal of Current Research and Academic Review, 3(9), pp.pp. 15-19.

Braber, K. (1995). Anaerobic digestion of municipal solid waste: A modern waste disposal option on the verge of breakthrough. Biomass and Bioenergy, 9(1-5), pp.365-376.

Gould, S. (2016). Plastic from bacteria – now in algae!. [online] Scientific American Blog Network. Available at: https://blogs.scientificamerican.com/lab-rat/plastic-from-bacteria-now-in-algae/ [Accessed 1 Oct. 2016].

Gross, R. (2016). Biodegradable Polymers for the Environment. Science AAAS.

Johnson, K. (2016). Degradation of Degradable Starch-Polyethylene Plastics in a Compost Environment. American Society for Microbiology, Applied and Environmental MicroBiology, 59(9), pp.1155-1161.

Negoro, S., Kato, K., Fujiyama, K. and Okada, H. (1994). The nylon oligomer biodegradation system ofFlavobacterium andPseudomonas. Biodegradation, 5(3-4), pp.185-194.

Royte, E. (2016). Corn Plastic to the Rescue. [online] Smithsonian. Available at: http://www.smithsonianmag.com/science-nature/corn-plastic-to-the-rescue-126404720/?no-ist [Accessed 1 Oct. 2016].

SBS Science. (2016). It won’t be long before all our plastics come from plants instead of oil. [online] Available at: http://www.sbs.com.au/topics/science/earth/article/2016/10/10/it-wont-be-long-all-our-plastics-come-plants-instead-oil [Accessed 1 Oct. 2016].

The University of Waikato, (2016). Biodegradability, compostability and bioplastics. [online] Sciencelearn Hub. Available at: http://sciencelearn.org.nz/Innovation/Innovation-Stories/Biospife/Articles/Biodegradability-compostability-and-bioplastics [Accessed 1 Oct. 2016].

Yang, J., Yang, Y., Wu, W., Zhao, J. and Jiang, L. (2014). Evidence of Polyethylene Biodegradation by Bacterial Strains from the Guts of Plastic-Eating Waxworms. Environmental Science & Technology, 48(23), pp.13776-13784.

Leave a comment